DL+ 12V 135Ah Now Just $999 — Limited-Time Summer Offer

As you can imagine, it has been quite a journey from only offering our two mainstay batteries to today’s custom solutions. But how did we get here? How did Dakota Lithium come to be? A good place to start would be with one of our founders and Chief Technical Officer, Michael Shope. Discussing all things Dakota Lithium, Michael takes us through the early days to our distinct red and blue color scheme to today’s custom OEM product design.

The Dakota Lithium concept grew out of our successes in the e-bike market. We’ve always had two locations: North Dakota and Seattle. After years of building experience with lithium batteries designed to power e-bikes, we started to test out our own more generic battery designs and found they were useful for many purposes other than e-bikes. We put out a few test products under the Dakota Lithium name and customers loved them!

Great question. We found most batteries are just boring looking, with black or grey colors. There are a few others with colors but most are a little wacky and wild and look like toys. We wanted to choose a look and feel that communicated exactly what people could expect from the Dakota Lithium technology, which is industrial-grade reliability, a unique balance of price, quality, and service, and American design work. The blue and red primarily connote reliability and innovation together, and the red-white-blue is also a nice subtle nod to the American assembly and engineering.

My favorite part about OEM/wholesale customers is the challenge of meeting all their design needs in the most elegant way we can find. We look at more than just the technical battery design. We set up an entire supply, production, and service plan for the wholesale customer so that their entire experience is carefully engineered, in addition to their battery itself. We have so many favorites. There’s a customer who deploys Dakotas in remote control submarines, others in off-grid ecological monitoring equipment, and many innovative remote power solutions for farming. It’s amazing what people have done with Dakota Lithium products!

Yes, we now assemble some of the Dakota products in Seattle as well, but we’ve always assembled in North Dakota. We do, of course, have many strong partnerships in Asia for supply of key components, and even some assembly, but American assembly processes allow us a much higher level of control, design communication and refinement, and customer service for both consumers and wholesale customers.

Oh boy! Yeah, there have been a lot of different opinions about how to get that concept out on the market. Basically, the challenge has been to get customers the same high quality, low price, and great service while offering them more powerful options for trolling motors and larger remote power systems. We found a lot of customers understood the concept of “putting a lot of small Dakotas together to make a big one” but were uncomfortable doing the wiring themselves. Some of our earlier designs of a pre-built, larger parallel power pack like the Vortexes were more bulky and/or delicate. With the neoprene and rugged velcro, we’ve found a fantastic mix of size, ruggedness, and cost that is making a lot of people really excited.

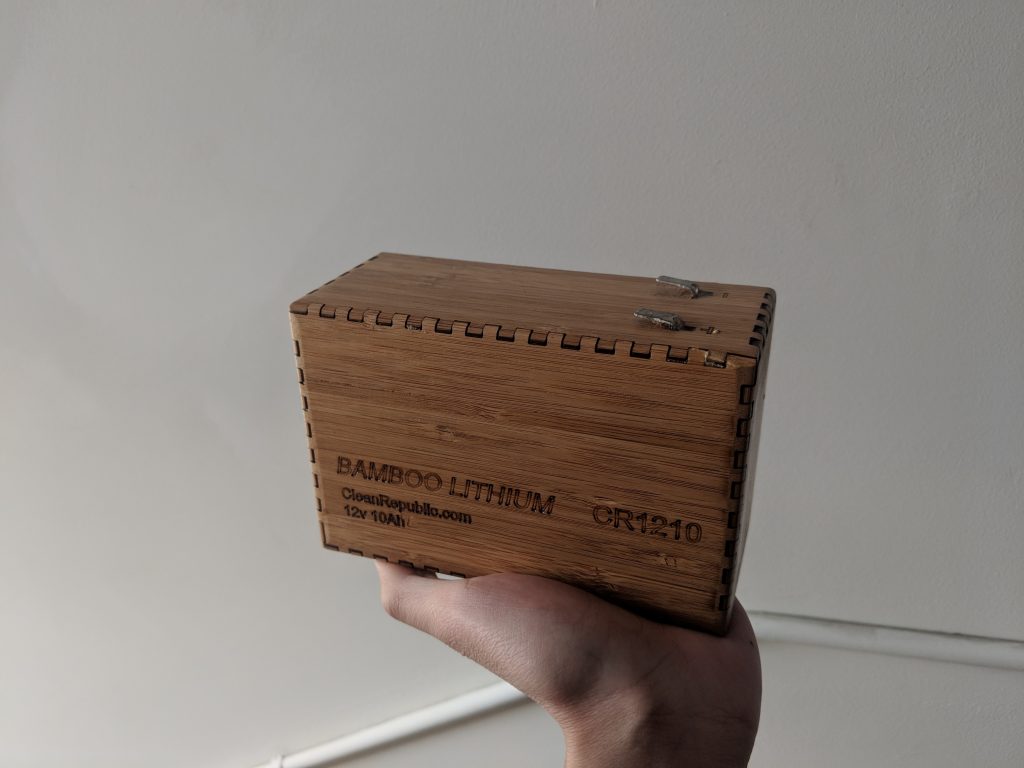

We have experimented with wood and bamboo cases in the past. We do want to get back to a few of those designs for some fun boutique options. We’re looking for any suggestions customers have in that area since one of our strengths is applying the lithium battery technology in areas and packages that are outside the traditional lines.

Absolutely. We’ve got a number of exciting projects in pre-launch testing right now, including remote solar charging options for all Dakota Lithium products, larger packs for electric vehicles, and even remote monitoring capabilities via new Internet of Things technology, so please let folks know to send us all their questions and ideas about what new products they’d like to see roll out!