Do I need a special charger for lithium batteries?

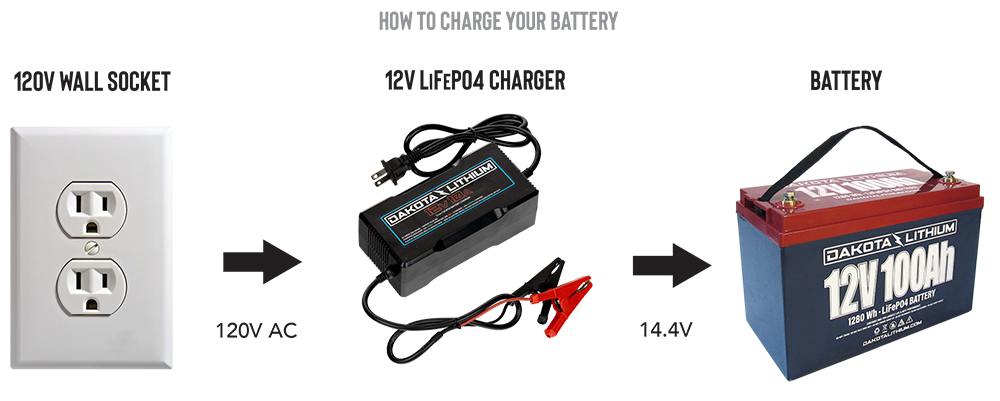

All Dakota Lithium and most lithium-ion batteries require a higher voltage than lead acid batteries to fully charge and perform best when charged with a lithium specific battery charger that charges at 14.4 – 14.8 Volts. This includes Dakota Lithium Iron Phosphate (LiFePO4) and Lithium Nickel Manganese Cobalt (NMC) batteries. A battery charger for a lead acid battery will work to partially charge a lithium battery, but only to a maximum of 60-80% of the lithium battery’s capacity. The voltage level of a full lead acid battery is about a volt lower than the voltage of a full lithium battery. As a result, the lead acid charger will think the battery is “full” once it reaches the lower voltage that is associated with a full lead acid battery. The result is lead acid battery chargers work, but only charge to 60-80% of the lithium battery’s capacity. Please note that lead acid chargers do not damage the battery, they just prevent the battery from reaching it’s full capacity and performance potential. The performance limitations of lead acid chargers being used for lithium batteries is significant enough that most lithium battery owners prefer to use lithium specific chargers. Lithium specific chargers maximize the performance and value of a lithium battery.

One exception is solar charge controllers. A solar charge controller transforms the energy produced by a solar panel to the ideal voltage to charge your battery. Solar charge controllers always perform better when they are lithium battery specific or have a lithium setting. Enough solar power is lost due to the inefficiency of a lead acid solar charge controller attached to a lithium battery that the solar panels may fail to adequately charge the battery. An example of a lithium specific solar charge controller would be the Victron SmartSolar MPPT 75/15 Solar Charge Controller. For more see the how to charge my battery from solar panels section below.

What voltage is required to charge my lithium batteries?

Dakota Lithium Iron Phosphate (LiFePO4) 12V batteries should be charged at 14.4 Volts (V). For batteries wired in series multiply 14.4V by the number of batteries. For example, a 24V battery bank requires a charger voltage of 28.8V , 36V requires 43.2V, etc.

Dakota Lithium Battery Voltage | Recommended Charging Voltage | Recommended Charging Speed (C)

12 Volts | 14.4 Volts | <0.3C (3 hours or more)

24 Volts | 28.8 Volts | <0.3C (3 hours or more)

36 Volts | 43.2 Volts | <0.3C (3 hours or more)

48 Volts | 57.6 Volts | <0.3C (3 hours or more)

How fast can I charge my battery?

Calculate the charge time by dividing the capacity of the battery (Ah for Amp Hours) by the charger output (A for Amps). For example, a 12V 100Ah Dakota Lithium battery includes a free 12V 10A LiFePO4 battery charger that charges the battery from empty to full in 10 hours (100 Ah divided by 10 A = 10 hours).

For the longest lifespan LiFePO4 batteries should be charged at less than .3C, or 3 hours or more of charging time. But all Dakota Lithium batteries can be charged at a rate of up to 1C and a charging time as low as 1 hour. For other brands confirm that max charging amps in the battery’s specifications. 0.5C (2 hours) is a common max charging speed for lithium batteries.

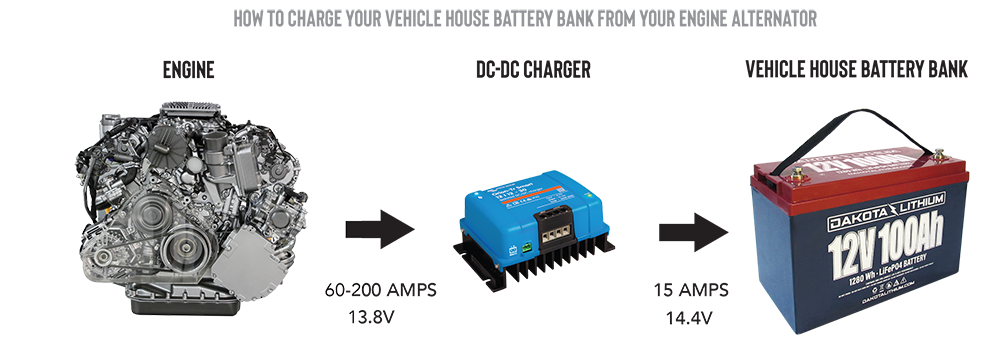

Charging time does impact lifespan. Charging at 1C / 1 hr regularly will reduce the lifespan of lithium batteries. The Lithium Iron Phosphate (LiFePO4) molecules that make up a Dakota Lithium, or any LiFePO4 battery, are stressed each time you charge a battery. Overtime those molecules fracture, break apart, and lose their ability to hold a charge. This is why after 2,000 to 4,000 recharge cycles at <0.3C a LiFePo4 battery will have <70-80% of the original capacity, and why Dakota Lithium batteries reach their half-life (<50% of capacity) at around 6,000 recharge cycles. A higher charge rate will increase the stress on the molecules, leading to a shorter battery lifespan. Therefore, Dakota Lithium recommends using a DC-DC charger like the Victron Orion-Tr Smart 12/12-18A Isolated DC-DC charger when charging your battery from the alternator in the engine of a car, van, or boat. This is because alternators commonly charge batteries at 1C or higher (to learn more see section Can I charge using my engine’s alternator).

Dakota Lithium Battery | Recommended LiFePO4 Charger & Charge Time | Faster Charger Option

12V 10Ah Battery | 12V 3A LiFePO4 charger (3 hrs) | 12V 10A LiFePO4 charger (1 hr)

12V 18Ah Battery | 12V 3A LiFePO4 charger (6 hrs) | 12V 10A LiFePO4 charger (1.8 hrs)

12V 23Ah Battery | 12V 3A LiFePO4 charger (8 hrs) | 12V 10A LiFePO4 charger (2.3 hrs)

12V 54Ah Battery | 12V 10A LiFePO4 charger (5.4 hrs) | 12V 20A LiFePO4 charger (2.5 hrs)

12V 100Ah Battery | 12V 10A LiFePO4 charger (10 hrs) | 12V 20A LiFePO4 charger (5 hrs)

12V 200Ah Battery | 12V 10A LiFePO4 charger (20 hrs) | 12V 20A LiFePO4 charger (10 hrs)

24V 50Ah Battery | 24V 5A LiFePO4 charger (10 hrs) | 24V 20A LiFePO4 charger (2.5 hrs)

24V 100Ah Battery | 24V 5A LiFePO4 charger (20 hrs) | 24V 20A LiFePO4 charger (5 hrs)

36V 63Ah Battery | 36V 8A LiFePO4 charger (8 hrs) | 36V 18A LiFePO4 charger (3.5 hrs)

36V 100Ah Battery | 36V 8A LiFePO4 charger (12 hrs) | 36V 18A LiFePO4 charger (5.4 hrs)

48V 96Ah Battery | 48V 8A LiFePO4 charger (12 hrs) | 48V 15A LiFePO4 charger (6 hrs)

Which lithium charger brand can I use for LiFePO4 batteries?

Most LiFePO4 chargers have an output of 14.6V – 14.8V which will charge Dakota Lithium batteries, and any LiFePO4 fully. Here at Dakota Lithium, we recommend using Dakota Lithium LiFePO4 chargers because they provide an optimal voltage of 14.4V, which slightly increases the battery’s lifespan by stressing the battery chemistry less during charging. Dakota Lithium LiFePO4 chargers also undergo our company’s redundant quality control process, ensuring every charger is optimized and safe to use with all our LiFePO4 batteries. Other programmable chargers can also be used if needed and should be set to output 14.4V and disconnected after charging. VRLA chargers and other lithium-ion batteries’ chargers do not output the correct voltage for charging the battery fully.

Can I charge my batteries with solar panels via a solar charger?

Yes, for smaller solar panels that are less than <60 watts you can connect the panel directly to the battery with little loss in efficiency or performance. The battery management system (BMS) in the Dakota Lithium will prevent over charging and stop charging from the panel once the battery is full. When using a solar panel that is 100 watts or larger to charge a battery then a LiFePO4 or lithium compatible solar charge controller is strongly recommended. For system with more than 200 watts of solar energy a solar charge controller is required for efficiency and safety. A solar charge controller takes the energy from the solar panels and turns it into the optimal voltage for charging your battery. For example, if you had installed a 100-Watt Solar Panel on the roof of your van or RV you would then need a Victron SmartSolar MPPT 75/15 Solar Charge Controller or similar sized solar charge controller to take the energy from the panel that is at 18 Volts (V) and transform it into 14.4 Volts, the optimal voltage for a Dakota Lithium or any LiFePO4 battery. The solar charge controller also increases the efficiency of the transfer of energy from the solar panels to the battery, increasing charge time and overall system efficiency. Approximately 100 – 200 Watts of solar power charges 100Ah of battery capacity depending on use and on climate and latitude. For example, if you use your boat or RV mostly on weekends you need less, if living on it full time you will need more. And if you are living in Canada, you will need more solar panels then someone living in Arizona.

Here’s a size chart for what size of solar panels is needed to fully charge one lithium battery.

Size of Battery | Recommended Solar Panel Capacity | Solar Charge Controller

12V 7Ah Dakota Lithium | 20-Watt Flexible Solar Panel | None

12V 10Ah Power Box 10 | 50-Watt Folding Solar Panel | None

12V 23Ah Dakota Lithium | 50-Watt Folding Solar Panel | None

12V 54Ah Dakota Lithium | 100-200-Watt Rooftop Solar Panels | 15 Amp MPPT Victron or Similar

12V 100Ah Dakota Lithium | 100-200 Watt Rooftop Solar Panels | 15 Amp MPPT Victron or Similar

12V 200Ah Dakota Lithium | 200-Watt Rooftop Solar Panels | 15 Amp MPPT Victron or Similar

12V 400Ah Dakota Lithium Off-Grid Power System | 300-Watt rooftop Solar Panels | 15 Amp MPPT Victron or Similar

Can I use an onboard charger to charge lithium batteries?

Yes, Dakota Lithium and all LiFePO4 batteries can be charged with onboard chargers. Pre-assembled wiring kits for connecting your batteries to onboard chargers are available here Trolling Motor Wiring Kits . If the onboard charger has a lithium setting, or can be set to 14.4V it will fully charge the battery. Chargers that do not go as high as 14.4V, such as onboard chargers for marine AGM or lead acid batteries that do not have a lithium setting will not be able to charge the battery fully. If possible, disconnect the batteries when they are completely charged.

Can I charge a lithium battery using my car, van, or boat’s alternator?

Yes, but only lithium and LiFePO4 batteries that are designed for automotive use can be charged directly by the alternator. For automotive or marine cranking applications where you are starting an engine and charging the starter battery from the engine’s alternator, we recommend the Dakota Lithium Plus 12V 60Ah Dual Purpose 1000 CCA battery. This battery provides up to 1,000 cold cranking amps to start a vehicle’s engine and can charge up to 80 Amps from a vehicle’s alternator. For most LiFePO4 batteries on the market, including all Dakota Lithium deep cycle batteries, a DC-DC charger is required to charge a lithium battery from an engine’s alternator.

Why is a DC-DC charger needed to charge a lithium battery from a car’s alternator?

DC-DC chargers are needed in most cases when using alternators to charge batteries (exception is the Dakota Lithium Plus 12V 60Ah 1000CCA battery which is designed for use in a boat or car’s engine). Without a DC-DC charger, an alternator’s power output can charge the battery at a rate more than 1C, which causes damage to the battery and may turn the battery off by triggering the overcharging protection in Dakota Lithium’s battery management system (BMS). Also, charging a large capacity ‘house bank’ of batteries via the alternator will cause it to run at full nameplate output power, which may overheat and/or damage the alternator. For alternator charging, a DC-DC charger is recommended, or the user may carefully review and choose a “DL+” model pack from our catalog and use it without a DC-DC charger in circumstances where the alternator output matches the battery charging abilities well.

Should I use float chargers or battery maintainers for my lithium battery?

No, LiFePO4 batteries should be disconnected from the charger when fully charged. Float charging, or maintainers are not good for lithium batteries. Keeping a constant float charge or topping off charge also can cause metal plating and will reduce the lifespan of lithium batteries. Dakota Lithium batteries also have a low self-discharge rate of <5% a month. This low self-discharge rate makes a battery maintainer for long term storage un-necessary (for more on battery storage see section below).

How do I know my charging is working?

The light on the battery charger turns green when plugged into an outlet. While charging, the light turns red. It turns green again when the battery is fully charged. The charger should be disconnected when the battery is fully charged to prevent over-charging which can cause permanent battery damage.

Why won’t my lithium battery charge? How to troubleshoot battery problems

Checking the battery and a charger with a voltmeter is a good place to start when experiencing issues. Test the battery before and after attempting a full charge, and when the battery is depleted. Also, test the output on the charger, it should measure 14.4V when working properly. Getting a voltage charge of less than 1V is evidence that the B.M.S. has been triggered on the battery to protect it from a potentially dangerous condition. The B.M.S. can usually be reset by charging the battery with a Dakota Lithium charger.

What is the battery voltage when my battery is full or depleted?

Batteries measure around 14.4V when they are fully charged and quickly drop to about 13.4V when the charger is removed. They provide consistent power between 13.4 to about 12.8V and quickly deplete to 9.7V at the end of the discharge. Dakota Lithium Iron Phosphate batteries have a flat voltage curve. This means that the voltage will be fairly steady throughout use, and only drop below a useful voltage when the battery is nearly empty. Lead acid batteries have a steep voltage drop and it is common that a lead acid battery’s voltage is no longer useable when the battery still have 60% of capacity left. This flat voltage curve is why Dakota Lithium batteries have twice the usable power even though the battery has the same amount of energy inside the battery. A 100Ah Dakota Lithium battery will last twice as long as a 100Ah AGM or lead acid battery even though the name plate or energy rating is the same. Please note: Seeing a low voltage of <1V is evidence that the B.M.S. is triggered.

What is the B.M.S.?

B.M.S. – Battery Management System – is the intelligent component of the battery which monitors and manages several aspects of its performance, including charge and discharge rates. The B.M.S. also provides safety protection in the case of short circuit, over charging, or the battery getting too hot. The B.M.S. will trigger and shut down the battery in instances when the charge/discharge current is too high, the temperature is too high, or to prevent over charging or over discharge. BMS design may vary with brand. Dakota Lithium engineers design the battery management system microchips for our batteries in house to meet specific safety standards including cold temperature charging protection, high temperature protection, cell balancing, and other features that extend the lifespan and performance of the battery. Please note: Seeing a low voltage of <1V is evidence that the B.M.S. is triggered.

How do I turn a battery back on after the battery management system has turned it off?

If available use a voltmeter to check the voltage of the battery. Seeing a low voltage of <1V is evidence that the B.M.S. is triggered. To re-start the battery simply connect to a Dakota Lithium LiFePO4 charger to the battery. The charger will tell the BMS inside the battery to turn on the battery and re-charge.

How can I calculate the battery’s run time?

Calculate the battery run time by dividing the battery capacity (Ah) by the power draw of anything connected to the battery (A). For example, an electric cooler that a power draw of 1 amp can be powered for 100 hours by a Dakota Lithium or LiFePO4 battery or 40-50 hours by an AGM or lead acid battery.

What happens inside my battery when charging or discharging?

Dakota Lithium batteries transfer a charge via lithium-ions between lithium iron phosphate in the cathode and graphite in the anode using intercalation. The ions never become lithium metal and stay in the ion state, which makes the batteries rechargeable.

At what temperatures can I charge and operate my batteries?

LiFePO4 batteries can be safely discharged below freezing temperature and provide up to 70% of their power, VLRA batteries do not work at that temperature. Dakota Lithium batteries can also operate safely in temperatures up to 149°F, while VRLA batteries’ service life halves every 18°F increase in temperature over 120°F. LiFePO4 batteries can be charged in environments up to 113°F but should not be charged in direct sunlight above 90°F. Charging lithium iron phosphate batteries below 32°F not only makes your batteries unsafe, but it also will drastically and permanently reduce the capacity.

How should I store my battery? Does it self-discharge?

LiFePO4 batteries have a low self-discharge rate of 3 – 5% per month, so they can be left in a partially discharged state for over a year without damaging the battery. This is 5X less than the self-discharge rate of VRLA batteries, but it is higher than some other lithium based systems.

L.F.P. batteries should be stored well charged at a temperature between 40 – 95°F, however, they need to be above 32°F to charge. We recommend charging your lithium batteries every two months to ensure they do not completely drain.

How do I use a voltmeter?

To use a voltmeter, first, make sure it is in DC (direct current) mode and then connect the red clip to the red/+ battery terminal and the black clip to the black/- battery terminal when measuring a battery’s voltage. Measure the voltage from a charger by touching the red clip to the positive contact point on the charger, and the black clip to the negative contact point.

How can I connect my batteries in series and parallel circuits?

The batteries can be connected in a string to increase the total voltage or capacity in a system, but batteries must match in all criteria including type, voltage, and amperage. Connecting two batteries in parallel combines their capacity (Ah), while connecting the batteries in series combines the batteries’ voltages. The batteries can be charged while in the system, by connecting a charger with matching voltage of the system to the positive terminal of the first battery and the negative terminal of the last battery.

How are Dakota Lithium batteries designed to work in Lead Acid battery systems?

LiFePO4 batteries are one-third the size of VRLA batteries of the same capacity, but they are designed to be “drop-in replacements” for 12V, 24V, 36V and 48V systems designed around lead-acid batteries. For example, four LiFePO4 cells in series can provide 12.8V, which can be used to replace systems made around traditional 6 2V cell batteries.

What if one battery loses charge faster in a circuit?

When batteries are connected in a series, they can become unbalanced, this can be detected by testing each battery with a voltmeter. Separately charging each battery can fix this issue.

Safety information:

Do not charge any damaged batteries.

Do not short circuit lithium batteries.

Do not heat over 140’F

Do not exceed the max discharge specifications of the battery (for example, if the battery has a max discharge of 10 amps do not try to run a trolling motor off of it that pulls 20 amps)

Do not puncture the outer case or disassemble the battery

Batteries over 300Wh are subject to hazmat regulations when shipping.

When shipping a battery plenty of anti static bubble wrap should be used to protect it from blunt damage. The terminal posts should be removed, if possible, to prevent accidental shorting.

Safety: How Safe are Lithium Iron Phosphate Batteries?

We have all heard and read past accounts of lithium batteries exploding or catching fire when compromised during trauma or over charging. But with the development of new chemistries and advanced manufacturing techniques, lithium ion technology is now one of the most popular battery options available. A common misunderstanding is that all lithium ion batteries are the same. There are different chemistries available that provide various advantages and disadvantages. Another factor in safety is the manufacturing of the battery and the technology of the battery including battery management systems (BMS) to monitor the battery’s performance.

BATTERY MANAGEMENT SYSTEM (BMS) – Ensures safety and long battery lifespan

All Dakota Lithium batteries include an active BMS protection circuit that handles cell balancing, low voltage cutoff, high voltage cutoff, short circuit protection and temperature protection for increased performance and longer life. Safety measures provided by the BMS prevent overheating. All Dakota Lithium batteries have a BMS that can support linking batteries in series or parallel.

LITHIUM IRON PHOSPHATE – LiFePO4

Different Li-ion batteries use different chemistries. Dakota Lithium exclusively engineers our batteries using lithium iron phosphate or LiFePO4 for short. Lithium Iron Phosphate batteries are the safest lithium battery chemistry. Unlike the cell phone battery in your pocket, or the laptop battery on your desk, the structural stability of LiFePO4 results in significantly less heat generation compared to

other lithium chemistries.

NO THERMAL RUNAWAY – Dakota Lithium cells do not produce oxygen

The main cause of fire or explosion of a lithium ion battery is due to the cells being compromised or ruptured, which causes thermal runaway. Without proper management, thermal runaway may result in fire. Dakota LiFePO4 is extremely stable and does not produce the oxygen needed to aid thermal runaway and unlike other lithium battery chemistries will not result in a catastrophic meltdown.

100% COBALT FREE – No rare earth elements

NCM and other lithium ion chemistries that contain rare earth elements such as Colton or Cobalt produce oxygen and toxic fumes when ruptured, leading to fire. Dakota Lithium does not contain rare earth elements, and does not produce oxygen or a fire.

CERTIFICATIONS – Tested and certified for safety and reliability

Dakota Lithium batteries are UN 38 certified and built from grade A cells. Dakota Lithium’s cells are UL1642 certified and have been tested per IEC62133 standards. UN Manual of Tests and Criteria certified, and meets all US & International regulations for air, ground, marine, and train transport. Select battery models are ISO Certified ISO 9001:2008 Quality Management System & ISO 14001:2004 Environmental Management System for use in industry applications. IEC62133 certifications and additional laboratory services are available as required by our OEM clients.

INSTALLATION & CARE – Treat your batteries right

When proper installation and battery care is followed, your LiFePO4 battery will be safe and reliable for many years. This includes making sure all connections are tight and proper wiring sizes are used, compatible chargers and charging components are used, and the batteries are used for purposes that they are designed for.